Zvinonyatsozivikanwa kuti kunaka kwecarbide saw blades kwakabatana zvakanyanya nemhando yezvigadzirwa zvakagadziriswa.Kusarudzwa kwakarurama uye kunonzwisisika kwecarbide saw blades kunokosha zvikuru pakuvandudza kunaka kwechigadzirwa, kupfupisa nguva yekugadzirisa, uye kuderedza kushandiswa kwemari.

Zvimwe unonetseka pamusoro pekusarudza! Ipapo ndapota verenga chinyorwa ichi nekushivirira, ndinovimba chinofanira kukwanisa kukubatsira zvakanyanya.

Carbide saw blades anosanganisira akasiyana ma parameter akadai serudzi rwe alloy cutter head, zvinhu zve substrate, dhayamita, nhamba yemazino, ukobvu, mazino profile, kona, uye aperture. Aya ma paramita anotarisisa kugona kwekugadzirisa uye kucheka kwekuita kwesaha blade. Naizvozvo, pakusarudza blade yesaha, zvinodikanwa kuti usarudze blade yesaha nenzira kwayo zvichienderana nerudzi rwemasaha, ukobvu, kumhanya kwesaha, gwara rekuona, kumhanya kwekudya, uye hupamhi hwemugwagwa wesaha.

Kutanga, kusarudzwa kwemasimende emhando dze carbide.

Anowanzo shandiswa marudzi ecemented carbide ndeye tungsten-cobalt uye tungsten-titanium. Nekuti tungsten-cobalt-yakavakirwa simende carbide ine zvirinani kukanganisa kuramba, inonyanya kushandiswa muindasitiri yekugadzira huni. Sezvo iyo cobalt yemukati inowedzera, iko kuomarara kwesimba uye flexural simba reiyo alloy inowedzera, asi kuoma uye kupfeka kuramba kunoderera. Sarudza maererano nemamiriro ezvinhu chaiwo.

Chechipiri, kusarudzwa kwe substrate.

1. 65Mn chitubu simbi ine elasticity uye plasticity yakanaka, ehupfumi zvinhu, yakanaka kupisa kupisa kuoma, yakaderera kupisa tembiricha, nyore deformation, uye anogona kushandiswa masaha blades anoda yakaderera kucheka zvinodiwa.

2. Carbon tool simbi ine high carbon content uye high thermal conductivity, asi kuoma kwayo uye kusapfeka kwekudzivirira kunodonha zvakanyanya kana kuine tembiricha ye200 ℃-250 ℃, deformation yekupisa yekupisa ihombe, kuoma kwakashata, uye nguva yakareba yekupisa iri nyore. kutsemuka. Gadzira zvinhu zvehupfumi zvematurusi.

3. Kuenzaniswa nekabhoni mudziyo simbi, alloy mudziyo simbi ane nani kupisa kuramba, kupfeka kuramba uye nani kubata kushanda. Kupisa deformation tembiricha i300 ℃-400 ℃, iyo yakakodzera kugadzira yakakwirira-giredhi alloy circular saw blades.

4. High-speed tool simbi ine kunaka kuomarara, kusimba kwakasimba uye kusimba, uye kuderera kusingadziviriri deformation. Iyo ndeye Ultra-yakakwirira-yakasimba simbi ine yakagadzikana thermoplasticity uye yakakodzera kugadzira yakakwirira-yekupedzisira ultra-thin saw blades.

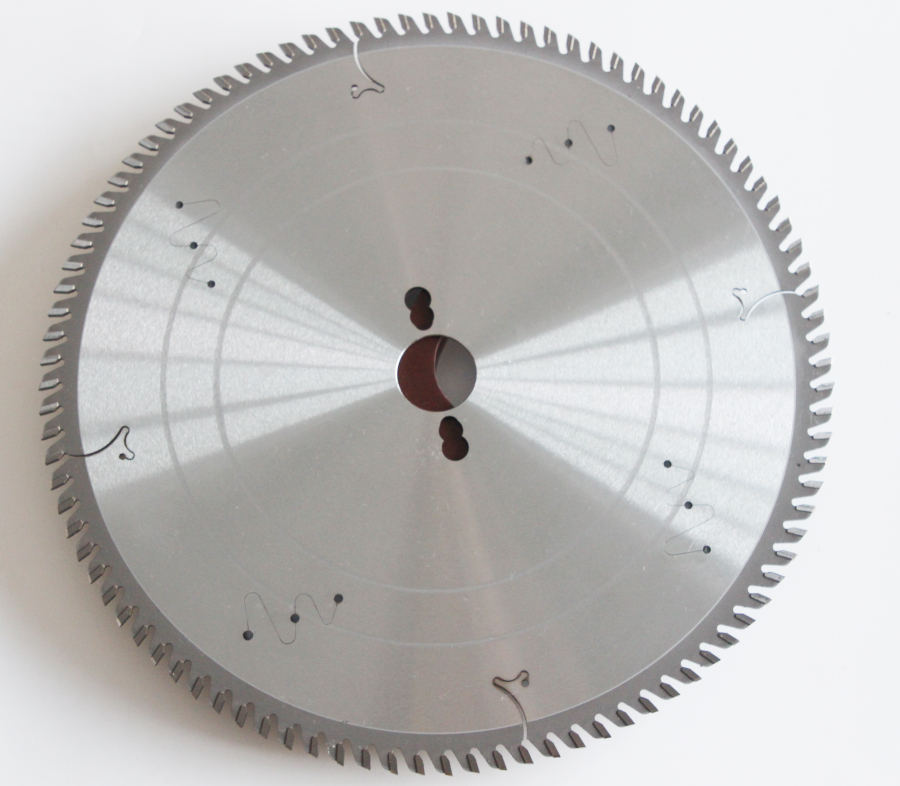

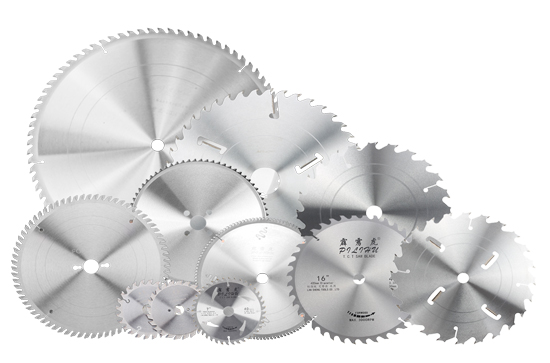

Chechitatu, kusarudzwa kwedhayamita.

Iyo dhayamita yesaha blade ine hukama nemidziyo yekucheka inoshandiswa uye ukobvu hweiyo sawing workpiece. Iyo dhayamita yesaha blade idiki, uye kasi yekucheka yakaderera; iyo yakakura dhayamita yesaha blade ine zvakakwirira zvinodikanwa pashizha resaha nemidziyo yekuchekeresa, uye mashandiro ekuona akakwira zvakare. Iyo yekunze dhayamita yesaha blade inosarudzwa maererano nemhando dzakasiyana dzedenderedzwa dzakaona.

Chechina, kusarudzwa kwenhamba yemazino.

Kazhinji kutaura, kuwanda kwemazino, iyo yakawanda yekucheka mipendero inogona kutemwa munguva yeyuniti, zviri nani kucheka kwekuita, asi mazino ekucheka akawanda anoda kushandisa yakawanda simende carbide, mutengo wesaha wakakwira, asi. mazino akanyanya dense , Chip volume pakati pemazino inova maduku, izvo zviri nyore kuita kuti blade isaha inopisa; uyezve, kune akawanda akawandisa akaona mazino. Kana huwandu hwekudya husina kufananidzwa, huwandu hwekucheka hwezino rimwe nerimwe hudiki, izvo zvinowedzera kukakavara pakati pekucheka uye workpiece, uye zvinokanganisa hupenyu hwebasa rekucheka. Kazhinji kuparadzaniswa kwemazino kunosvika 15-25mm, uye nhamba inonzwisisika yemazino inofanira kusarudzwa maererano nezvinhu zvinotemwa.

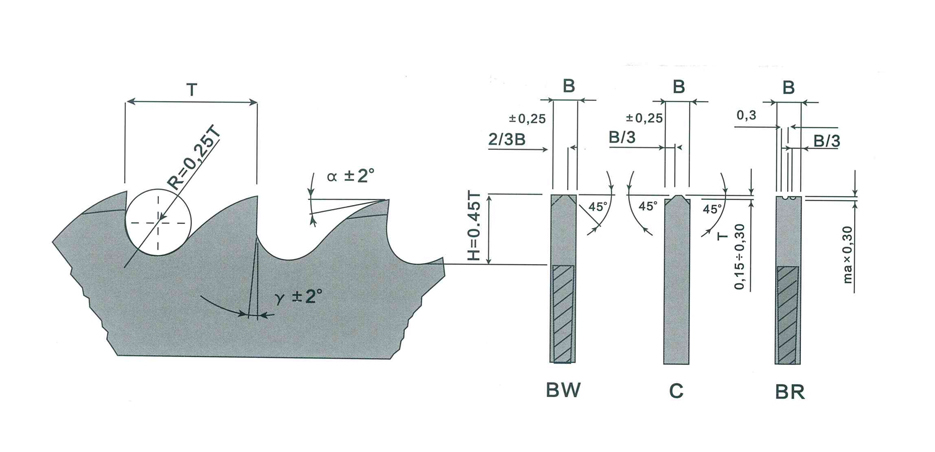

Chechishanu, kusarudzwa kwezino profile.

1.Mazino ekuruboshwe nekurudyi ndiwo anonyanya kushandiswa, kukurumidza kucheka kunokurumidza, uye kugaya kuri nyore. Yakakodzera kucheka uye kuyambuka sawing akasiyana-siyana akapfava uye akaoma akasimba ehuni profiles uye density board, akawanda-layer board, particle board, etc. Mazino ekuruboshwe nekurudyi akashongedzerwa nemazino ekudzivirira anodzivirira mazino enjiva, akakodzera kureba. kucheka kwemarudzi ose emapuranga ane nodes yemiti; zino rekuruboshwe nerekurudyi remasaha ane negative rake angle anowanzo shandiswa kunamira nekuda kwemazino akapinza uye kunaka kwekucheka, ayo akakodzera mapaneru.

2. The flat tooth saw blade yakaoma, kasi yekucheka inononoka, uye kugaya ndiyo iri nyore. Inonyanya kushandiswa pakucheka matanda akajairika, ane mutengo wakaderera. Inonyanya kushandiswa kune aluminium saw blades ane madhayamita madiki kuderedza kunamatira panguva yekucheka, kana grooving saw blades kuchengetedza pasi pegororo rakati sandara.

3. Ladder flat mazino ari musanganiswa we trapezoidal mazino uye sandara mazino. Kukuya kunowedzera kuoma. Inogona kuderedza kuputika kweveneer panguva yekucheka. Yakakodzera kucheka kweakasiyana-siyana ega uye kaviri veneer huni-based mapaneru uye mabhodhi asina moto. Kuti udzivise kunamatira, aruminiyamu saw blades anowanzo kushandisa masaha ane nhamba huru yemazino emanera akati sandara mazino.

4. Mazino emanera akapidiguka anowanzo shandiswa pazasi slot saw blade yepanera saw. Pakuona iyo yakatarisana-yakatarisana nehuni-yakavakirwa pani, iyo slot inogadzirisa ukobvu kuti ipedze grooving yepasi pepamusoro, uye ipapo main saw inopedzisa kusevha kwebhodhi. Dzivirira kuputika kwemucheto mumucheto wesaha.

Nguva yekutumira: Oct-11-2021